An unprecedented opportunity for Vietnam to build an autonomous industry

TTO – Capital flows have shifted and a series of multinational corporations have stepped up investment in Vietnam. The opportunity for Vietnamese businesses to join the global supply chain has never been as great as it is today.

THACO’s mechanical products are not only limited to supplying cars but also to many other industries. In the photo: workers at THACO factory, Quang Nam province – Photo: HUU HANH

Many Vietnamese businesses have taken advantage of this. However, the presence of giants such as Intel, Samsung, Foxconn … and their suppliers, while many Vietnamese enterprises are not qualified to supply components, is posing a challenge. great for Vietnam in building an autonomous industry.

Seize the opportunity to rise

During the 2 years of the pandemic, the global supply chain was turned upside down, causing many industries to suffer because of a lack of spare parts. For the auto industry, there have been at least 3 car models manufactured and assembled in Vietnam that had to be suspended due to a lack of production components. But few people know that many Vietnamese businesses have explored and seized the opportunity to rise.

Mr. Huynh Quang Nhung, deputy general director of Thaco Industries, said that more than 5 years ago, Thaco focused on manufacturing more components, and mechanical processing based on technology from many complementary industries.

The potential of the mechanical industry, according to the forecast of the Ministry of Industry and Trade, is 310 billion USD.

In preparation, when the US-China trade war occurred, Thaco took the opportunity to export semi-trailers, expected to export 15,000 vehicles in 2022 with a value of more than 200 million USD. Currently, Thaco Industries is also rushing to receive orders from FDI enterprises looking to order mold production

Instead of customers ordering a lot of partners to perfect the product, they now choose businesses that can shorten the process, time and optimize costs.

In companies where they only process one product, when an error occurs, it is unlikely that they have enough equipment and machinery to fix it immediately. Thaco focuses on technology capacity, production processing capacity, and the advantage of integrating many business lines of Thaco such as sea and road logistics to reduce costs for customers.

Thaco now collaborates with numerous partners as a result of that. Even Australia, Canada, Mexico, Italy, and other countries that export semi-trailers to the US market provide designs and prices to locate and order semi-trailers.

Meanwhile, with Hanoi Plastic Joint Stock Company, Mr. Bui Minh Hai, chairman of the Board of Directors, said that in 2021, despite the impact of the COVID-19 epidemic, the project to produce TV covers for export to India The degree of An Trung Industries, a member company of Hanoi Plastics, with Foxconn customers has come into stable operation and brought economic efficiency.

Automobile production at THACO factory in Chu Lai (Quang Nam) – Photo: HUU HANH

Many translations target Vietnam

Panasonic Corporation (Japan) said it will promote the expansion of production and sales of wiring devices, lighting equipment, and IAQ equipment (indoor air quality equipment) in Vietnam. This is the latest event in the transformation chain that makes Vietnam the first choice for Panasonic to implement its value chain optimization strategy after the company closed 2 refrigerators and washing machine factories for 2 years. before in Thailand.

Having conservation with Tuoi Tre, Ms. Hoang Thu Thuy, senior vice president, and head of the global purchasing management department of Panasonic Vietnam said that Panasonic’s two refrigerator and washing machine factories have been invested in since 2005. In 2003, the R&D center was born in 2005. This is a center of international scale and stature in Vietnam and a center in Southeast Asia for research and development of household products to supply to Vietnamese consumers and export to other Asian countries.

“According to the world’s custom, manufacturing plants often have R&D centers located near the parent company in Japan. However, with Panasonic’s two areas of the refrigerator and washing machine manufacturing, the R&D center located in Vietnam has the advantage in deciding all production activities, such as making fundamental changes in design, materials, and products to neighboring countries, helping the production process to be more optimized, reduce costs,” Ms. Thuy said.

Despite difficulties caused by the pandemic, many businesses still increased investment and expanded production. The Vietnam Association of Supporting Industries – VASI has just announced notable information: Apple has moved 11 factories of Taiwanese enterprises in the supply chain to Vietnam. Similarly, many other enterprises such as Foxconn, Luxshare, Pegatron, and Wistron also expand their available scale in Vietnam.

As recorded, announcements such as “French enterprises looking for manufacturers of hand tools with hammers, wrenches, and screws; US companies looking for suppliers of a large number of auto accessories…” are increasing more on VASI’s website.

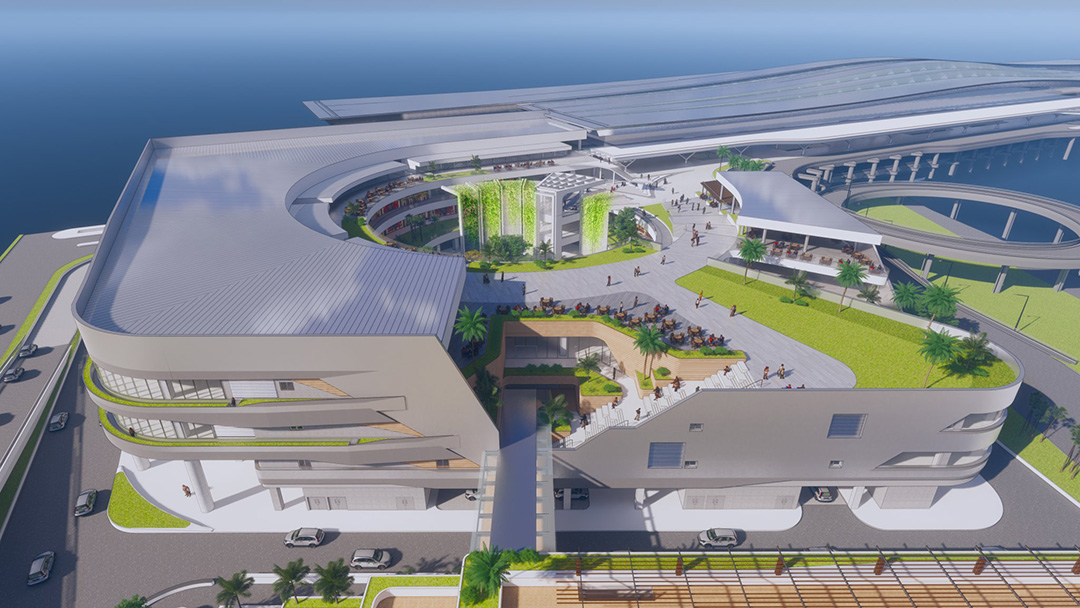

Technical Industries (TTI) is a multinational corporation, specializing in electrical and household appliances, with 12 factories globally, 76% of its products are supplied to the US and Northern European markets. Launched an investment project of USD 650 million in Ho Chi Minh City Hi-Tech Park. This company continuously organizes activities to find more than 200 domestic suppliers in Vietnam in 4 fields: plastic injection, mold, electricity, and metal.

For long-term development investment opportunities, TTI determines to use 80% of domestic supporting industry products. However, this rate has only reached a rather modest figure: 40% and the rest must be imported from China and the US.

Production workers work at a Panasonic factory – Photo: NGOC AN

Not easy to entrance

Although there are many advantages of shifting investment and expanding production in Vietnam, according to Ms. Hoang Thu Thuy, this does not mean that many suppliers in Vietnam will be able to join the production chain of Vietnam. Panasonic. Up to now, Vietnamese suppliers account for 51% of the volume but only about 35% of the value at the company.

At Panasonic Vietnam, there are 7 factories currently, and the demand for developing new products every year is very high. But, because there is already a pre-formed supply chain, to meet the increased orders when moving from Thailand to Vietnam, Panasonic still prioritizes ordering with existing suppliers.

“In the long term, when demand increases, we will develop suppliers in Vietnam to increase safety and ensure the sustainability of production activities of the entire chain,” Ms. Thuy shared frankly: the number of Vietnamese enterprises that meet the standards set by multinational corporations is very few, just a “minority”.

Normally, FDI enterprises in Vietnam will have more opportunities due to better quality management, delivery time, service…

Developing a domestic supplier in Vietnam to increase the localization rate with Samsung is also not a simple problem. Especially when this group has invested in 6 factories to turn Vietnam into the world’s leading large smartphone factory.

A representative of Samsung Vietnam said that the company initially organized seminars and ancillary industry exhibitions to find domestic suppliers. Then there are consulting programs to improve labor productivity and product quality by Korean experts directly “hand in hand”. Then train more than 406 Vietnamese consultants…

Up to now, with 379 businesses being consulted and improved, productivity has increased by an average of 30%, and even some enterprises have increased by 90%. However, the number of Vietnamese level 1 suppliers currently able to penetrate Samsung’s chain is only 51.

Source: Ministry of Industry and Trade – Data: N.AN – Graphics: T.DAT

Source: Tuoi tre

| HVACR Vietnam 2022 – The leading exhibition on Heating, Ventilation, Air conditioning Air filtration, and Purification Refrigeration Systems in Vietnam. The exhibition showcases the latest products, technologies and solutions from domestic and international manufacturers and suppliers, offering many business opportunities and relationships. Additionally, HVACR Vietnam is also an industrial platform to update the recent industry information from leading industry experts in the community.

ABOUT HVACR Vietnam 2022 |